Random & Structured Tower Packings

Random Tower Packings

RVT’s random tower packings are available in a multitude of geometrical configurations as well as materials and sizes for almost every application:

- Hiflow® rings

- Raflux rings (pall rings)

- RMSR (metallic saddle rings)

- saddles (plastics and ceramics)

- cylindrical rings and biological carriers.

Materials available:

Plastics

PP, PE, PPH, HDPE, PVC, C-PVC, PVDF, PFA

Metals

Carbon steel, stainless steel, hastelloy, titanium, nickel, copper, aluminium

Ceramics

Stoneware, alumina

Structured packings

Materials available:

RVT Process Equipment GmbH provides a broad range of innovative and conventional structured packings in both metallic and thermoplastic materials for different applications.

RMP and RMP S (RVT Metal Structured Packing) are mainly used in processes with:

- low liquid flow rates

- high gas loads

- for low pressure

- drop requirement

- high demand of

- mass transfer units

These operating conditions are common in many vacuum distillation and rectification processes in the chemical and petrochemical industry.

Hiflow® PLUS is a product that combines the advantages of random tower packings and conventional structured packings while reducing the limitations of these two mass transfer components.

This packing type – inspired by the Hiflow® random packing – is particularly suitable for applications that require high capacities at even greater liquid loads. Typical application fields are processes with large gas volumes e.g. CCS or SO2 separation processes from flue gases by means of scrubbing.

The main performance characteristics and advantages of Hiflow® PLUS are:

- lower pressure drop than that of random tower packings

- improved cross flow compared to conventional structured packings

- economic production due to reduced raw material requirement

- no redistribution (wall wiper) required

- easy installation

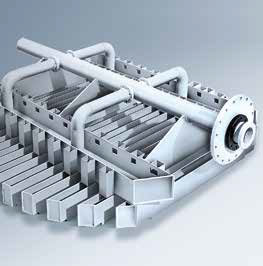

Column Internals

Mass transfer performances as well as the hydraulic characteristics of a packed column are substantially determined by the quality of the column internals used. The optimal adaption of the internals to the selected tower packings as well as to the individual operating conditions and material requirements require comprehensive

process engineering know-how and experience.

RVT Process Equipment is your competent and reliable partner in terms of the following items:

- liquid distributors

- collecting trays

- liquid feed systems

- bed supports and limiters

- mist eliminators

- gas distributors

- custom made internals for special applications

All these components are manufactured either in plastics or metals in our own factory. On demand we manufacture special materials like PTFE, TFM, CFC, titanium, tantalum.

Mass Transfer Trays

We offer mass transfer trays in versatile designs and materials for almost all applications including the hydraulic design.

RVT Process Equipment GmbH supplies valve, sieve and dual-flow trays, bubble cap trays, tunnel trays and also special tray constructions (cascade- or chimney trays, shower decks and trays for foaming systems).

Beside metals also thermoplastic materials can be used (PPH, PE, PVC, PVC-C, PVDF, PTFE, TFM).

Package Units

Based on the scope of supply of mass transfer equipment, the know-how and many years’ experience, RVT Process Equipment delivers plants for some specific applications:

especially

- cleaning of flue gases and process gases,

- the removal of ammonia and other volatile

- components from waste water by stripping processes,

- the combustion of gaseous and liquid residues and

plants for the separation of substances by thermal - separation processes.

Our scope of supply includes

- basic and detailed engineering,

- provision of all the necessary plant components,

- erection and assembly,

- commissioning and start up,

- service and maintenance.

Biological Carrier Media

An effective waste water treatment facility is an essential premise for ensuring a clean environment.

One of the main process steps in a waste water treatment plant involves the degradation of organics by microorganisms.

RVT Process Equipment is delivering the optimum carriers for this application. The scope of supply includes the carriers for submerged beds and trickling filters RFK and the carriers Bioflow for MBBR (Moving Bed Biofilm Reactors).